![]()

![]()

![]()

Pre-production of the 3RWorks Modern Tank Car The work is going on at the pre-production tank cars. Here are a few pics from the activities:

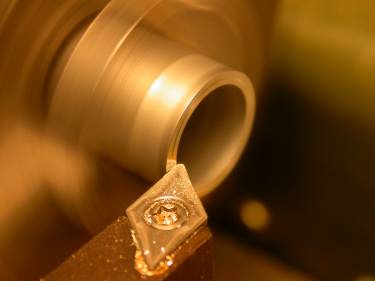

Turning of bolster pins and domes.

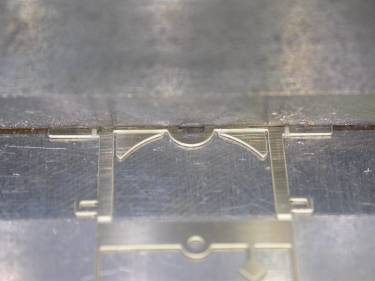

Pre-cut of tubes for the tank.

Turning to length and for exactnes.

Drilling of the holes for domes and bolster pins. Placing lead-weights.

Gluing of the elliptical end to the tube.

Applying bondo to the surface and preparing for the bolster pins.

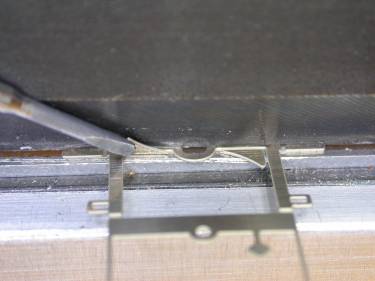

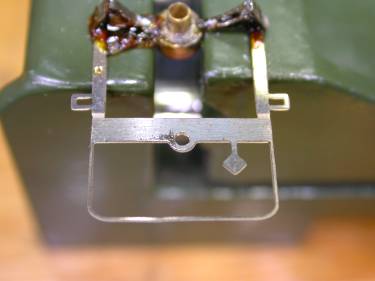

The "Bender" is used to fix the etching of the car's end. The bending is done by a small screwdriver.

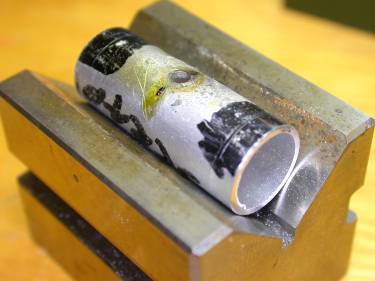

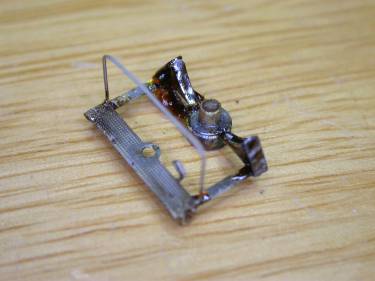

A piece of tube with a hole is placed in a prisma to work as soldering jig. The bolster pin is flame soldered to the end. Heat up the bolster pin and then put the soldering tin on the bolster pin.

The tank support is soldered.

Next step is bending and soldering the platform. The final operation is bending the steps.

A coat of primer is applied to the 30' and 50' proto.

Then the tank car is painted with glossy paint, the decal fit best to a glossy surface! After drying a clear coating with a matte finish is airbrushed on. 3RWorks will produce these tank car in a small series in autumn 2005. See more information on the 3RWorks Homepage: |

![]()

Powered by  http://www.3RWorks.com

http://www.3RWorks.com