![]()

![]()

![]()

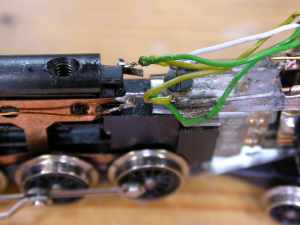

The energy is in the tender New at the RRR! This Mikado is the test engine for the electronic flywheel:

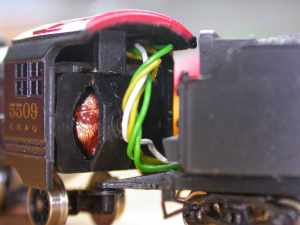

Wiring is done first time with super flexible wires. The engine is actually working for the R&D department and does not wear the RRR livery, also all wires aren't blackened for better visibility. One further novelty is the energy buffer for dirty track. By using SMD Tantal Capacitors electric energy is collected during normal operation, on a dirty piece of track they are discharging into the motor of this engine. This helps very well also on switches. The decoder is a Zimo MX62. Due to the fast and competent help from Mr. Ziegler of the needed soldering points at the decoder could be easily identified.

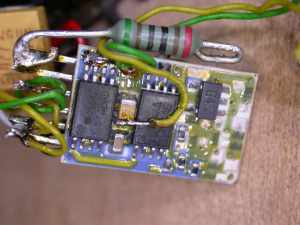

The leads of the buffering capacitor are soldered to the common positive and negative pole of the decoder. The positive one is mentioned in the decoder manual, you can see it at the left corner of the decoder. The negative pole is on the small cap between the two 8-feet transitors (yellow cable). On the right picture you see on the left corner of the decoder the originally installed 22 µF cap. Solder leads to this cap and connect to an additional 470 µF capacitor. The improved capacity of this for maintaining the decoder internal 5V control power. The "huge" resistor is for the headlight LED.

Here you see the "Powerpack" out of the tender and there into the tender. The cap on the left side is the additional

internal cap for the decoder. You wonder what a dent is in the chassis and on the tender side wall

Well that are the results from some R & D trial and error issues - What is it good for? Watch the small mpeg1 video or a

|

![]()

Powered by  http://www.3RWorks.com

http://www.3RWorks.com

The steel weight and the clips on the tender chassis have been removed to gain

space for the power-pack. All - decoder, buffer capacitor and auxiliary

cap - fits now smoothly in the tender.

The steel weight and the clips on the tender chassis have been removed to gain

space for the power-pack. All - decoder, buffer capacitor and auxiliary

cap - fits now smoothly in the tender.